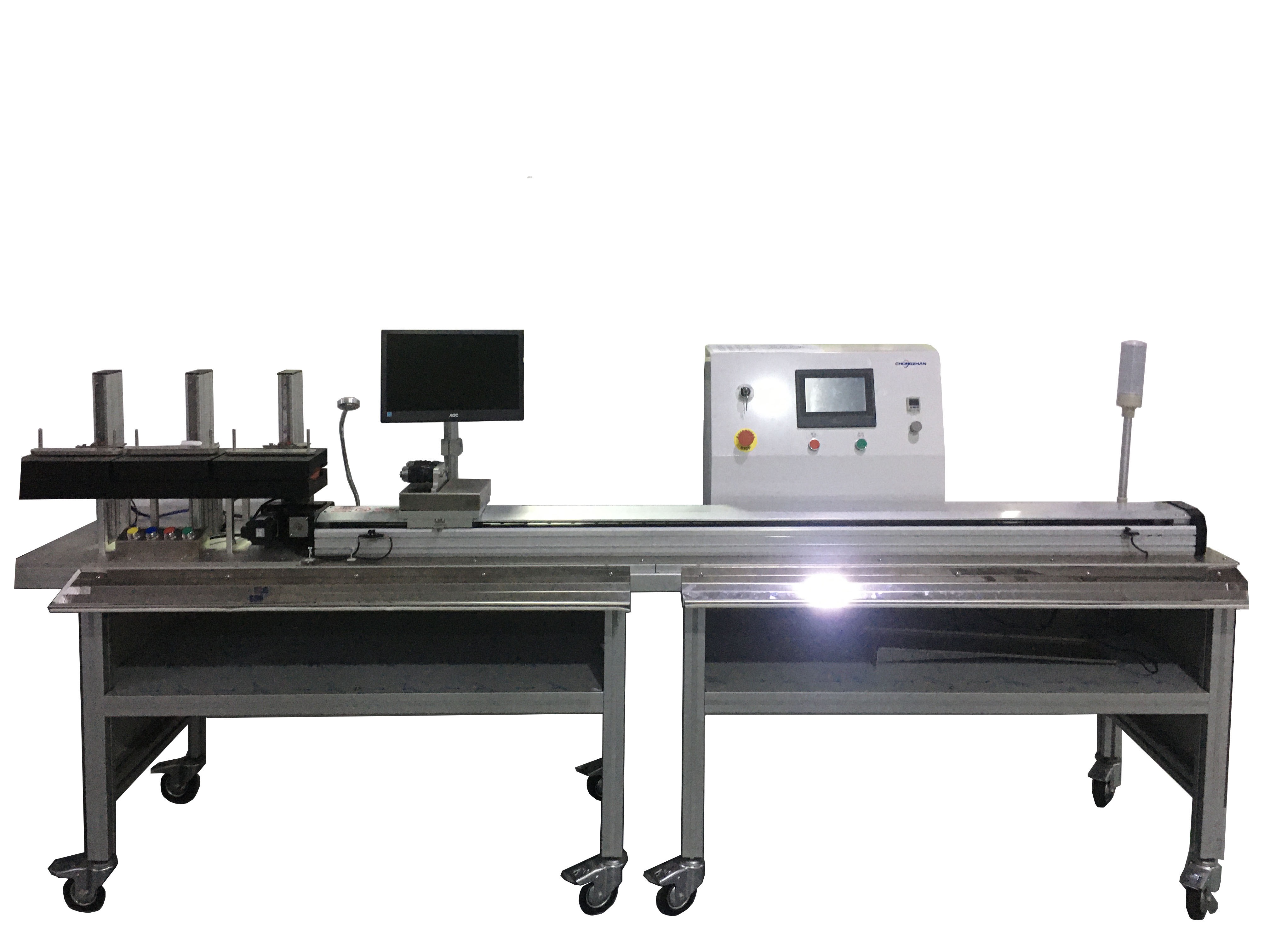

Shanghai Chongzhan mandrel-pulling machine:

The mandrel pulling machine uses the principle of dynamic friction to pull the mandrel in the microcatheter away.

The equipment has a tension control system and a speed monitoring system to automatically control the operation process. The device software interface is clear, simple and easy to operate.

Electrical parameters | Others | ||

Model | CZCX-1800 | Fixture spacing (anti-winding spacing) | 60 mm |

Input voltage | AC210~230V;50Hz | Force sensor range | 0~50kg |

Maximum power | 500W (Safe current carrying:220V 2.5A) | Accuracy of force sensor | 0.5 |

Ambient temperature and humidity | 5~40℃,0~75% RH (Non-condensing) | Minimum force resolution | 0.1g |

Air pressure | 0.6Mpa≤P≤0.75Mpa | Stroke | 0~1800mm |

Motor | servo motor | Speed | 0~100mm/s |

Control core host | Mitsubishi PLC | Running accuracy | ±0.02mm/s |

Camera magnification | 470K(pal) | Process parameter file storage quantity | 20(More options) |

Display resolution | 1366*768 | Separation method | Three-segment free-standing |

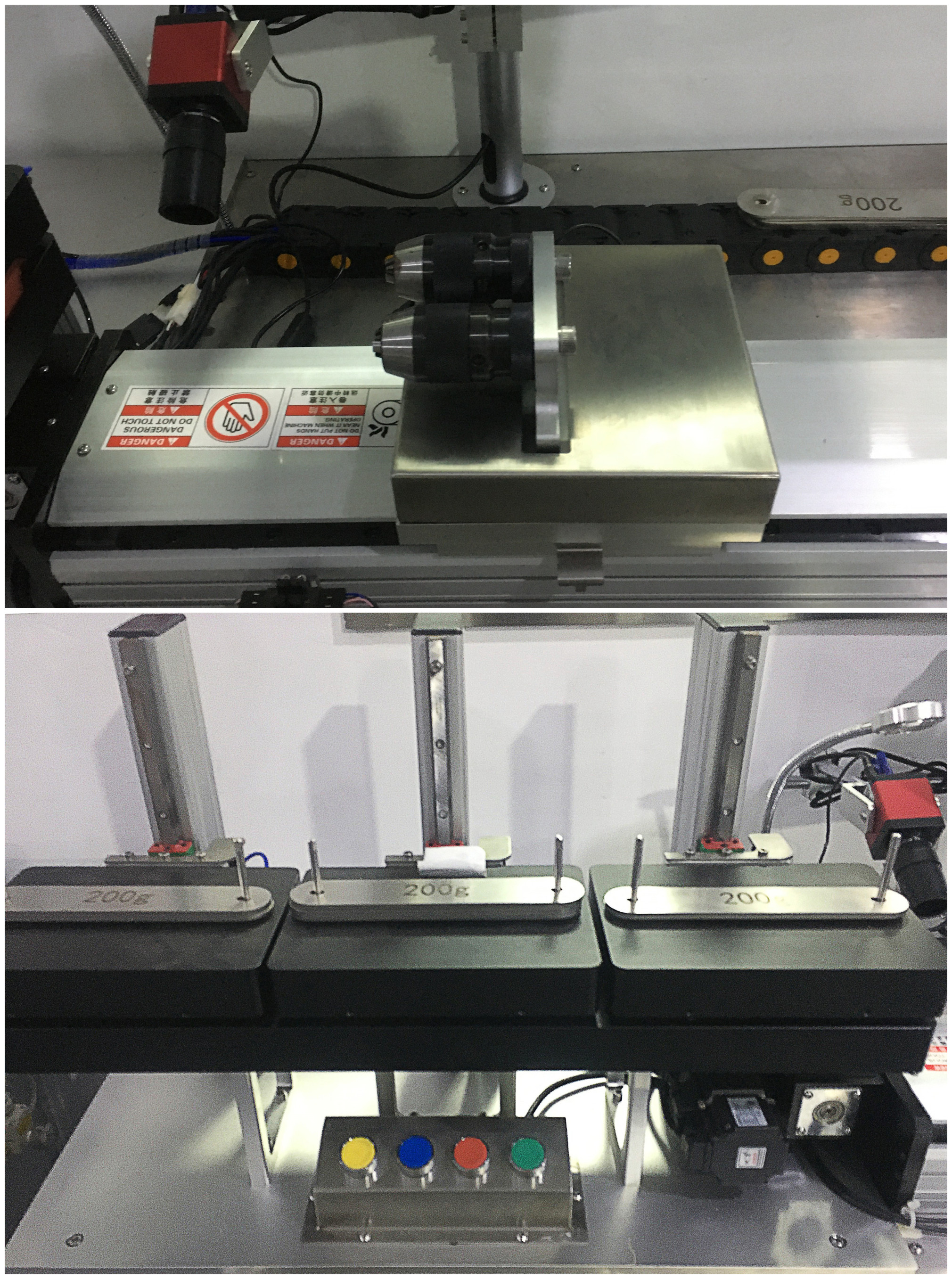

Size | L*W*H=3500 × 700 × 1400 (mm) | Clamping force control method | Three independent weights |

Device Description:

a.Camera and 15-inch display:The camera can observe the state of the front end of the product during the production process and display it on the screen, which is convenient for operators to observe.

b.Product holding unit:During the production process of this equipment, two products can be held simultaneously. During the production process, the operator can read the friction between the current product and the separation speed of the current product on the human-computer interaction interface.

c.Control box:The control box integrates modules such as a control panel and a human-computer interaction interface, which is convenient for the operator to control the device and read the current operation.

d.HMI:The human-machine interaction interface adopts a large-scale screen. The real-time pulling force value can be enlarged and displayed, and the upper and lower limits of the pulling force can be set to monitor the pulling force in the production process. At the same time, the human-computer interaction interface can artificially set the running speed of the product production process, and can realize the segmented accelerated running mode.

e.Track:The core wire movement track of the product production process, the longest stretched product is 1800mm.

f.Product placing table:The product placing table is provided with two slots, which can place processed products and unprocessed products separately.

Welcome

Please point meClick to inquiry

Contact us:

+86-021-58646500