The balloon forming machine blows the balloon tube in the form of heat radiation, and finally forms a balloon. The balloon forming machine integrates a tension system, a temperature control system, and a high-pressure system into a multi-loop closed-loop system. The operating parameters of the equipment are fed back in real time and the system automatically adjusts according to the set parameters. The equipment is highly integrated, easy to operate, and saves labor and site costs.

Model | BFM-3300 |

Voltage | AC210~230V;50Hz |

Maximum power | 800W |

Input air source | Clean high-pressure nitrogen and compressed air |

High pressure nitrogen P1 | 3.5Mpa≤P1≤5Mpa |

Compressed air P2 | 0.5Mpa≤P2≤0.7Mpa |

Ambient humidity | 20~75% (non-condensing) |

Ambient temperature | 5~55℃ |

Balloon Forming Pressure Medium | High Pressure Nitrogen |

Balloon shaping output pressure range (nitrogen) | 0~5Mpa |

Balloon molding mold heating temperature range | 0~150℃ |

Axial linear temperature uniformity of straight die | ±2℃ |

Roughness of inner surface of flat die and end die Ra | 0.4 |

Applicable balloon length | 0~300mm |

Applicable balloon outer diameter | Φ2~Φ8mm |

Control system mode | Programmable automatic control |

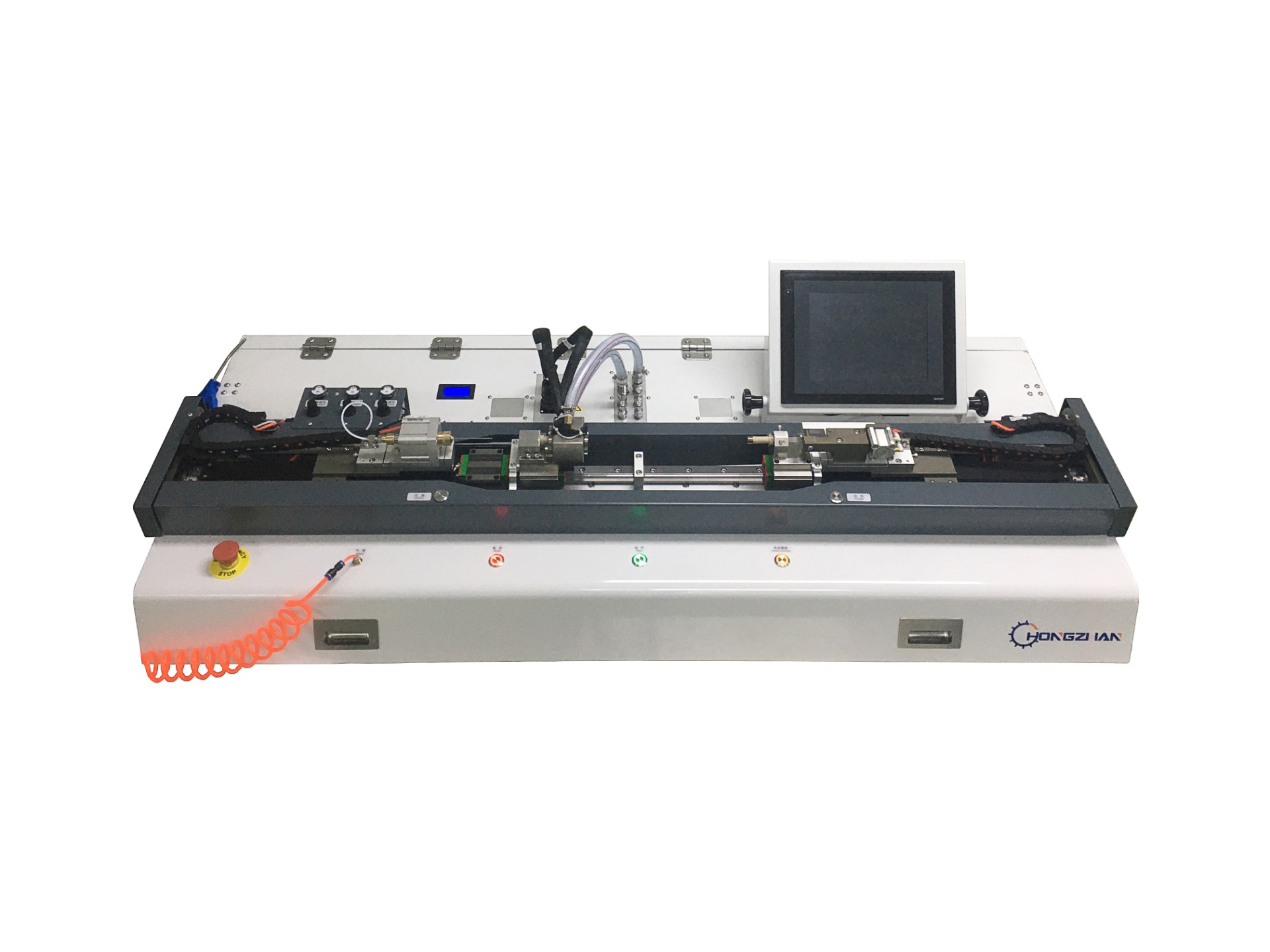

Device Description:

a.Left high-pressure clamp assembly: It can realize the clamping and pulling operation of the balloon tube. At the same time, during the balloon blowing process, the air needle assembly inside the left high-pressure clamp can seal the balloon tube and fill it with high-pressure nitrogen,and so on. The inside contains a precision tension sensor, which can monitor the balloon tube tension during the drawing process.

b.Control buttons: Buttons that control the movement of the device, such as: start, stop, reset, lock and release of left and right clamps, etc.

c.Right interception clip assembly: It can realize the operation of clamping, pulling, and intercepting the balloon tube. The inside contains a precision tension sensor, which can monitor the balloon tube tension during the drawing process.

d.Human-computer interaction interface: The operator interacts with the equipment for information.

e.Instrument panel: integrated with: air pressure adjustment and display, temperature display, current display, electrical interface, water cooling interface, convenient for operators to adjust and participate in the adjustment of the device.

f.Water jacket body assembly: The water jacket body assembly includes: mold heating, temperature feedback, water cooling cycle, mold opening and closing, etc. It is the core module of balloon forming.

Welcome

Please point meClick to inquiry

Contact us:

+86-021-58646500