The laser bonding machine is suitable for welding polymer materials. The device uses laser energy to weld polymer materials together, such as nylon, polyvinyl chloride, polyurethane, PET and other polymers.

The whole process of welding the polymer materials is visualized, the welding points are enlarged, and infrared laser welding is used to facilitate the confirmation of welding spots in batches of materials. Laser energy and welding methods are more material adjustable.

Equipment clamping products have high concentricity, stable operation, simple operation, simple and effective.

Model | CZCL-3600A/B或4100A/B |

Voltage | AC210~230V 50HZ |

Maximum power | 1600W |

Ambient temperature | 5~40℃ |

Ambient humidity | 0~75% RH(non-condensing) |

Control core host | Mitsubishi PLC |

Main cooling fan | Ball axial fan |

CO2 laser energy power adjustment range | 0.4W~6W |

CO2 laser energy stability | ≤3% |

Beam size | 0.3~4.0mm |

Rotary motor speed | 0~1100RPM |

Protective door | standard |

Laser moving speed | 0~5mm/s |

Movement speed accuracy | 0.1mm/s |

Laser running distance | 0~400mm |

Automatic spot size adjustment | Installed |

Automatic workpiece clamping system | Installed |

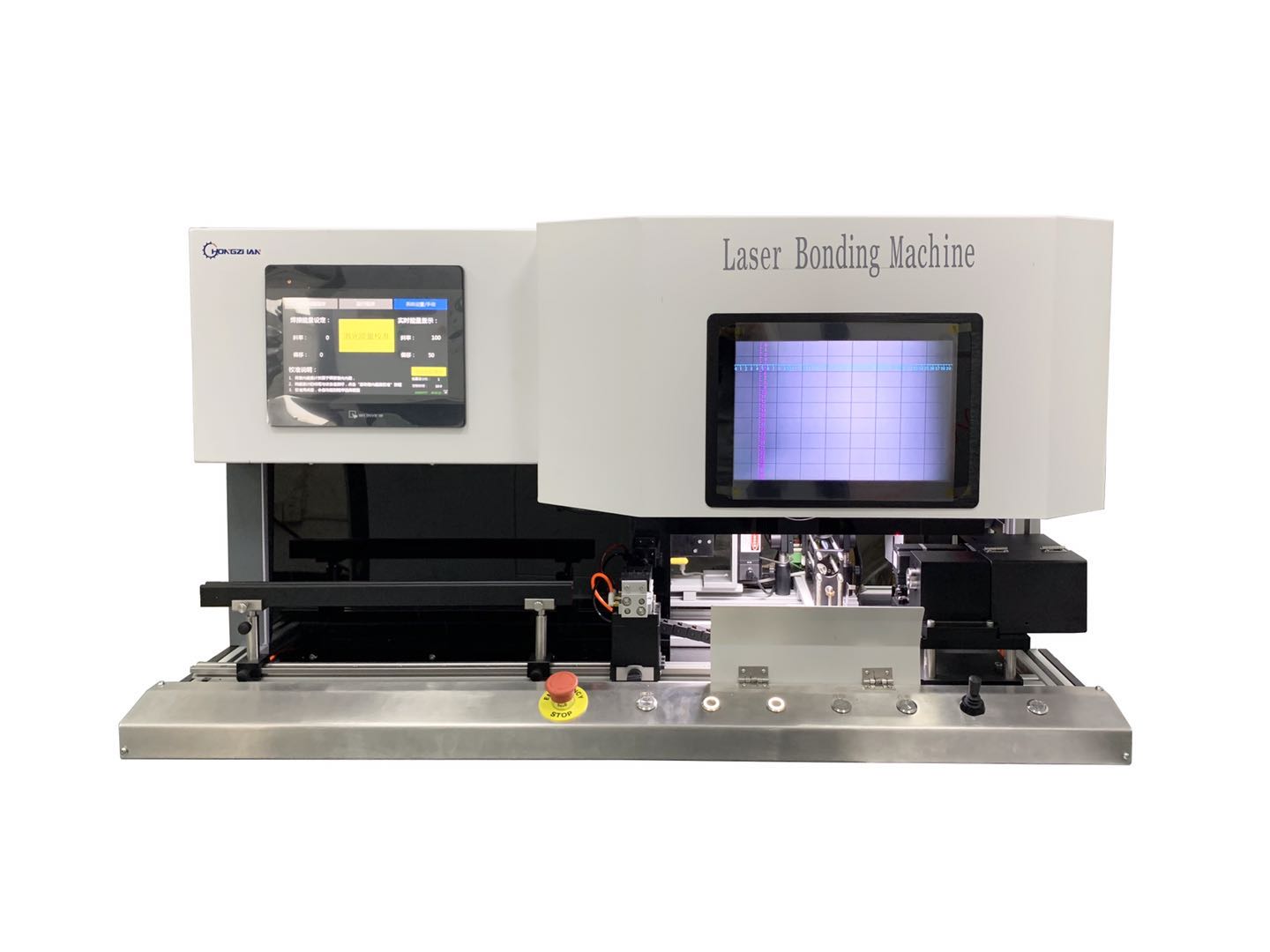

Device Description:

a.10.2 inch human-computer interaction interface: The interface for the operator to read and enter the operation information of the device.

b.Cross generator adjustment panel: Adjust the position where the crosshairs of the display coincide with the laser.

c.Power switch: the interface where the device is powered on and the main switch of the device.

d.Air source interface: the connection port of the device air source.

e.Extension bracket: The operator chooses to use the extension bracket to support the product according to the needs of the processed product.

f.Emergency stop button: used to interrupt the circuit and all programs during the operation of the equipment.

g.15-inch display: real-time monitoring of processing status.

h.Plasma air gun interface: The interface for connecting the equipment to the plasma air gun, which has the functions of dust removal and anti-static.

i.Energy calibration serial port: a serial port for calibrating the energy of the device.

j.Automatic four-wing spring clamp:a device that automatically clamps the product at the right end of the device.

k.Automatic double-wing chuck:a device that automatically holds the product at the left end of the device.

l.Control buttons: Some buttons of the device such as start, run, stop, etc.

Welcome

Please point meClick to inquiry

Contact us:

+86-021-58646500