Shanghai Chongzhan Friction Tester is used to test the lubricity, firmness and fatigue of the surface coating of catheter guide wire products. At the same time, the equipment simulates the human body environment and similar operating environment, which makes the test results real and effective.

The equipment uses IPC to precisely control the module stroke and speed. At the same time, it monitors the statistical force value in the background, summarizes and report, which is convenient for operators to intuitively get the lubricity and firmness status of product coating.

The machine is easy to operate and work efficiently.

Input Voltage | AC220V;50Hz | Vertical module pull speed | 0~100mm/s |

Full load power | 1500W | Vertical tension sensor accuracy | 0.02% |

Security measures | Overcurrent protection and leakage protection (operating current ≤ 30mA) | Vertical module position reset accuracy | 0.02mm |

Measured product range | 0~300mm | Clamping pressure sensor detection range | 0~2kg |

Applicable product diameter | 0~10mm | Clamping module position reset accuracy | 0.02mm |

Clamping pressure sensor accuracy level | 0.02% | Water circulation temperature range | Room temperature~50℃ |

Number of test cycles | Can be set any number of times | Detection range of vertical tension sensor | 0~300g |

Clamping feed speed | 0~10mm/s | Maximum volume of water tank | 180*100*390mm |

Water cycle temperature control accuracy | ±1℃ | Interface size | 15 inch |

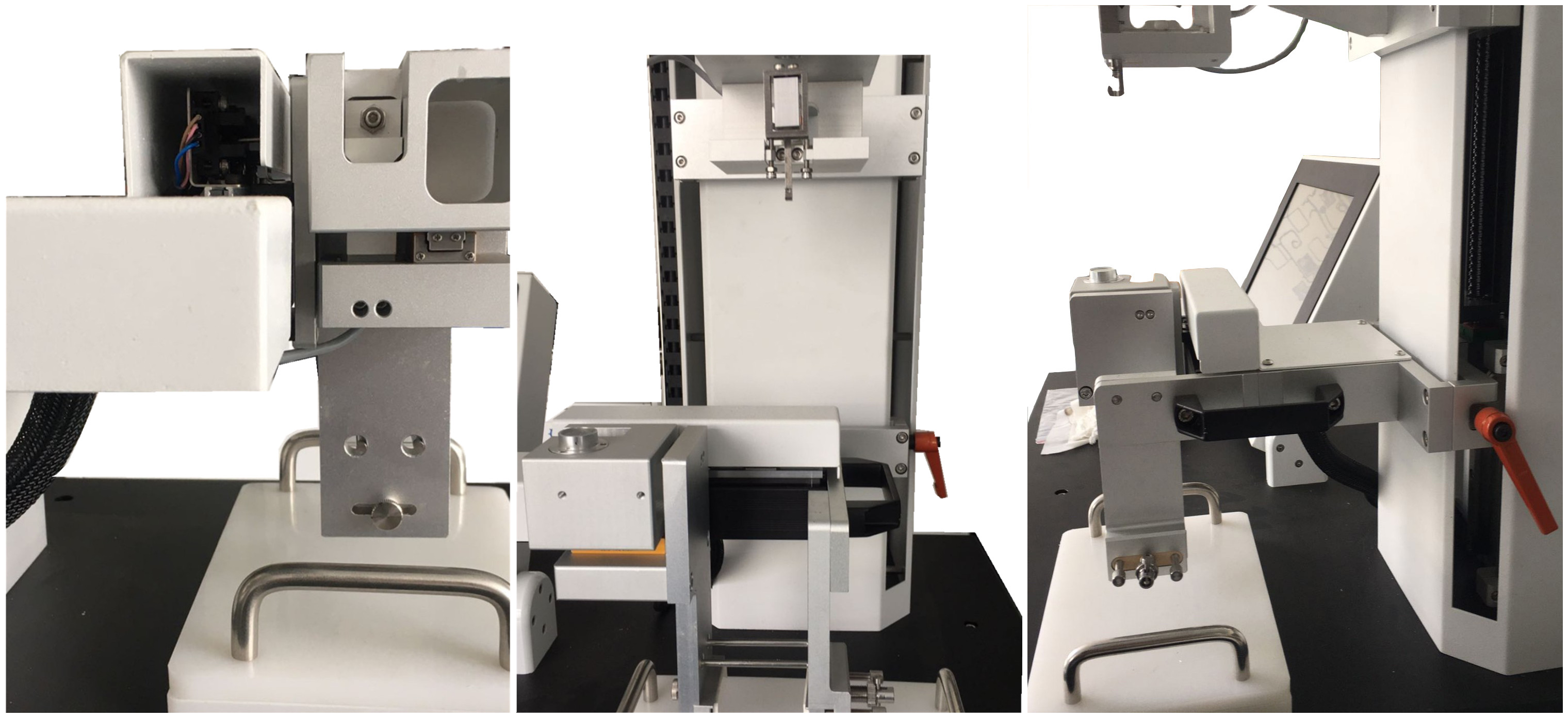

Device Description:

a. HMI: human machine interface, a platform for information transmission between operator and machine.

b. Key switch: the main switch of the equipment power.

c. USB port: The port for the operator to download data or to input data to the computer.

d. Emergency button: used to interrupt the circuit and stop all running of the equipment during operation.

e. Main modules platform: A platform for equipment to hold and move products up and down.

f. Clamp: to hold the products.

g. Thermostatic water tank: to simulate the operation environment of the catheter.

h. Cooling air outlet: air outlet for heat dissipation of the machine.

i. Universal wheels: convenient to carry.

j. Electric control case: there are integrated circuits, to facilitate the maintenance of circuits.

Welcome

Please point meClick to inquiry

Contact us:

+86-021-58646500